When it comes to electrification, automakers have options. They can spend untold billions to design and engineer new EVs from the ground up, or they can modify existing products, proven cars and trucks that are already in production. Both strategies have advantages and disadvantages, but supplier company ZF is making it much, much easier for car companies to electrify today’s crop of pickups, SUVs and vans thanks to a new product called eBeam Axle.

As the name suggests, eBeam Axle is an electrified drivetrain assembly that can easily bolt into existing truck-based vehicles. This product packages major components – the electric motor, power inverter, reduction gearing, parking lock, brakes, software and more – in one compact assembly that fits in the space of a conventional live axle.

ZF demonstrated the eBeam Axle in a heavily modified Chevy Silverado 2500 HD pickup. The rig’s gasoline engine and transmission were given the old heave-ho and the supplier’s electrified assembly was installed, along with 210 kilowatt-hours of battery and all the associated wiring and cooling hoses needed to make everything work.

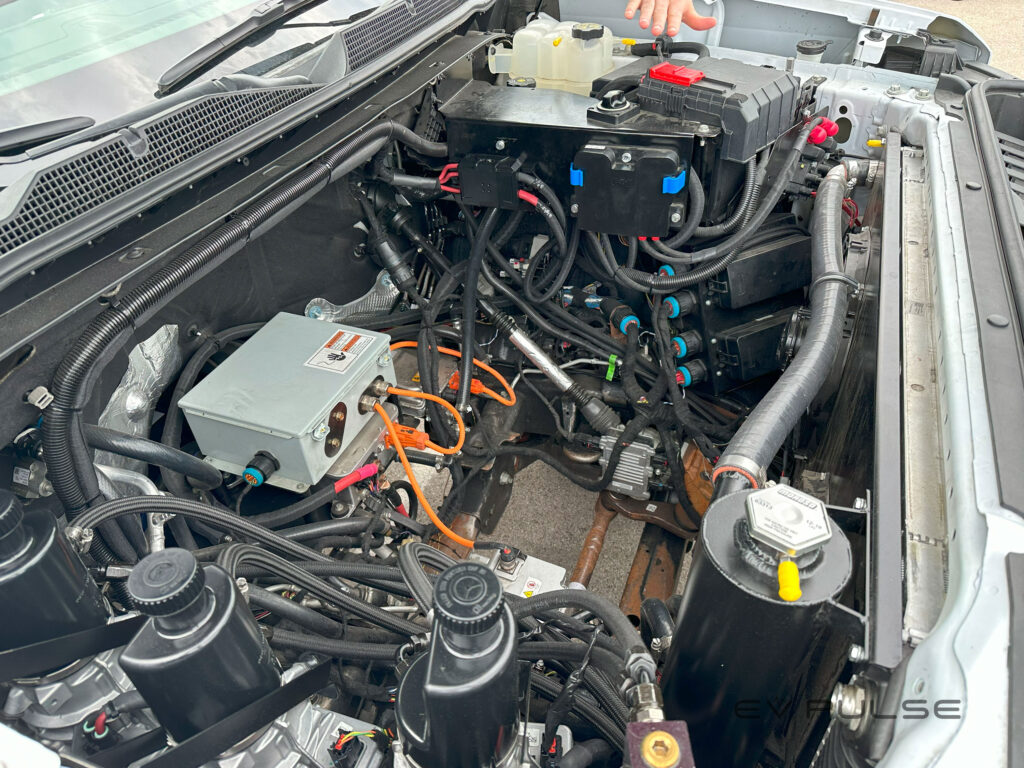

Popping the hood to take a peek reveals just how gargantuan this Silverado’s powertrain compartment is. You can’t really appreciate how much space a combustion engine and its associated components take up until all that’s been removed. Of course, this cavernous space is not completely empty. The truck has several electrically driven hydraulic pumps to run the power steering and braking systems, plus the cabin is heated and air conditioned, so there’s additional hardware to run those systems, but still, there’s a whole lot of room under this truck’s hood, space that could be utilized for myriad other purposes.

During a recent demonstration drive, Ryan McAlister, engineering project leader for the ZF eBeam Axle explained that the power inverter is water cooled and the motor is internally cooled by oil. Keeping drivetrain temps in check is critical to delivering the performance – and efficiency – automakers expect. Heat dissipation is handled at the front of the truck, just like the combustion powertrain.

In this application, the eBeam Axle features a permanent-magnet electric motor that delivers about 402 horsepower and 516 pound-feet of torque, though a range of outputs is expected to be offered, anywhere from 180 kilowatts (241 hp) up to 350 (469 hp). Additionally, this system is designed to support both 400- and 800-volt battery architectures, giving OEMs flexibility.

On the rigorous EPA test cycle, ZF estimates this implementation of eBeam will provide around 250 miles of range, which isn’t too bad for a heavy-duty pickup, one that can tow up to 10,000 pounds. Additionally, this technology is designed for long-haul durability; it can be used in personal vehicles, like high-end versions of the Silverado HD, or even commercial vehicles.

Putting ZF’s eBeam Axle to the test on a short drive revealed that the technology works as intended. It moves the 9,800-odd-pound pickup with relative ease and, aside a slight bit of jerkiness from the rear at times, is mostly smooth. OEMs will undoubtedly further polish this system when it lands in production vehicles.

ZF engineers also included six different drive modes with this implementation of eBeam Axle. There’s Economy, which limits torque output to 65%; Normal; Dynamic, which delivers 100% of the system’s torque; and three separate tow/haul settings that alter how aggressive the regenerative braking is when you lift off the accelerator pedal. The drive modes offered, what they do and how they’re tuned is something automakers would decide for themselves.

ZF’s eBeam Axle is not currently in production, but McAlister said it is very close to being ready. He also mentioned the company is developing a steerable eBeam system for use at the front of vehicles. This would allow OEMs to fully electrify their heavy trucks and commercial vehicle quickly and with relative ease.