The humble drum brake, an old-school automotive technology, could be making a comeback. German supplier company Continental is developing a completely dry braking system, one that’s electronically controlled, requires zero brake fluid and, oddly enough, is of a drum design. Overall, this setup offers numerous and impactful benefits and may even help improve the efficiency of electric vehicles.

SEE ALSO: 2024 Polestar 2 gets significant range and performance upgrades

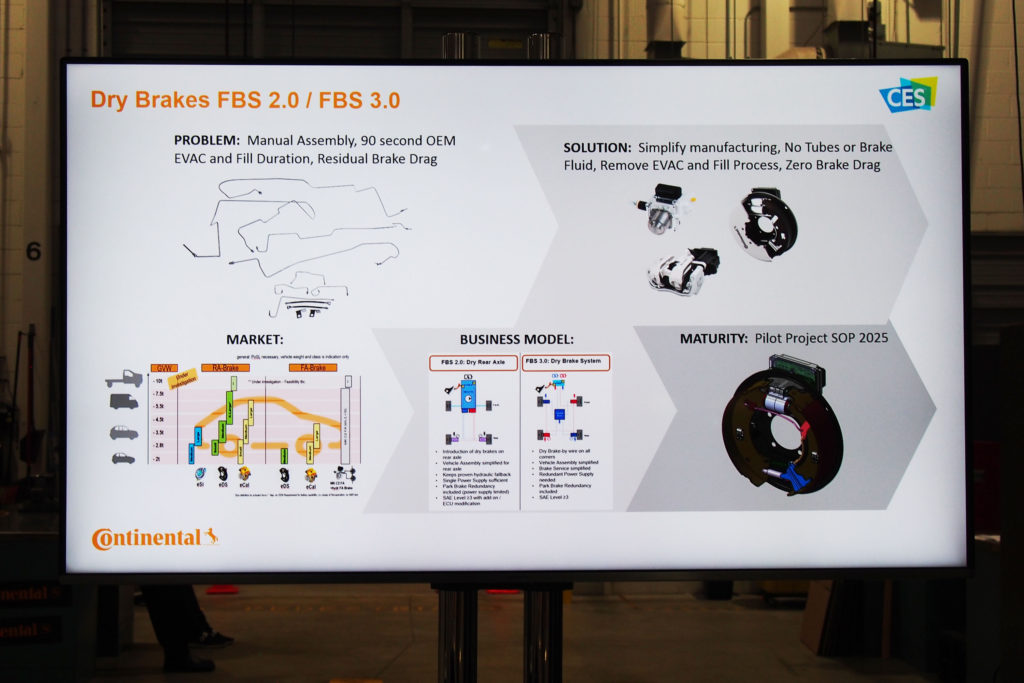

With a fluid-less braking system there’s no need to run individual lines from a master cylinder or ABS module to each wheel, components that often have to be hooked up by a human worker. Additionally, eliminating these tubes reduces vehicle weight and cuts complexity, but it also saves time on the assembly line, at least 90 seconds according to Leah Burns, project director for FBS 2 at Continental. She said it takes about a minute and a half to fully bleed a braking system, that is, remove all the air from the fluid and lines, so the brakes slow your car down properly when the pedal is pressed.

Eliminating the need for brake fluid is also a very good thing for people and the environment. As Burns explained, this substance is caustic, can eat paint, it absorbs moisture over time and is even known to cause cancer. “So, if we can get rid of brake fluid, it’s a huge benefit,” she added.

But why is Continental going with a ostensibly outdated drum design when disc brakes are almost universally accepted as the superior choice? Well, in part it comes down to efficiency.

“Electrification is certainly one of the things we focus on because … we are reducing some of the modules in the vehicle because of it, so we’ve got weight savings there,” said Burns. “This design system also supports zero drag. So, your typical (disc) brake system has friction surfaces that are always rubbing,” with drums this can be eliminated, which helps improve vehicle efficiency, however slightly.

Generally speaking, drum brakes don’t perform as well more modern disc-based systems. But the ability to quickly dissipate heat to resist fading is much less of an issue in EVs than combustion-powered vehicles because electrics also have regenerative braking, which does a large amount of the stopping, sending energy that would normally be wasted right back into the battery pack. Basically, when regeneration is factored in, the reduced performance associated with a drum-style braking setup is negated.

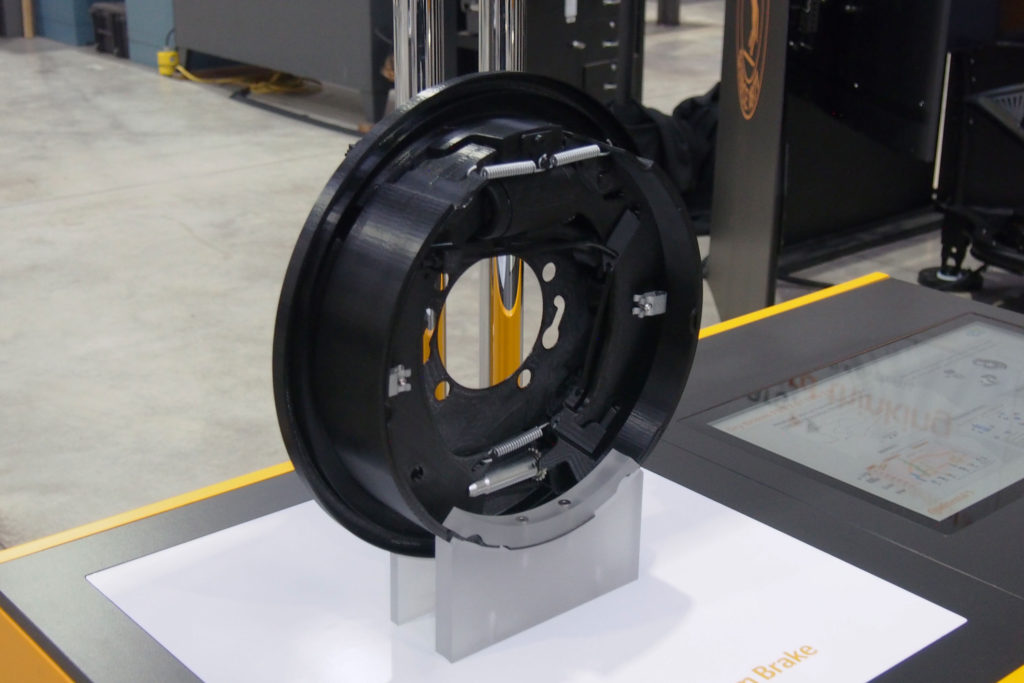

Continental’s dry braking system features an electric actuator motor and a ball-screw drive to push the shoes against the drums. As Burns explained, they opted for a dual-servo design, which spreads both shoes at the same time for enhanced stopping power. Beyond that she said, “There’s an integrated, redundant park brake in there to support it as well.” A proprietary design, it uses no cables.

CHECK THIS OUT: Lectron V-Box 48-amp EV charging station hands-on review

The technology is not currently available, but Continental expects its dry braking system to hit the market sometime in 2025. “It’s something that a lot of OEMs are looking for, smart solutions for their manufacturing,” said Burns. Aside from reducing vehicle-assembly complexity, eliminating nasty brake fluid and reducing frictional losses, this braking system should also be extremely versatile, applicable to all manner of applications. “The goal is really across the market, passenger cars and lightweight commercial vehicles,” said Burns, “It really supports the full range.”