You often hear about rare-earth elements and how they’re used in electric motors and other high-tech applications. But what are these metals and why are they so important? For answers, we chatted with Tom Schneberger, the CEO of USA Rare Earth, a Tampa, Florida-based company working to supply domestically sourced rare-earth metals.

Looking at the periodic table of elements, there are 17 rare-earth elements including Europium, Lanthanum, Promethium and Thulium to name a handful. “They are generally split into two categories. People talk about light rare earths and heavy rare earths,” explained Schneberger. “The most important light rare earth as it relates to magnets is neodymium, which a lot of people talk about neodymium magnets,” though he also noted that many of the other light rare earths don’t have much commercial value today.

The heavies are where it’s at — at least when it comes to manufacturing permanent-magnet electric motors — because of their strong magnetic properties and stability in adverse conditions. USA Rare Earth’s mine, located near El Paso in west Texas, contains predominantly heavy rear-earth elements including dysprosium and terbium, “which are used to produce magnets that can perform at higher temperatures,” said Schneberger, an estimated 1.2 million metric tons of rare earths. Their mine will also be a rich source of so-called tech metals like gallium and hafnium, but the deposit is also estimated to contain some 500,000 metric tons of lithium, another sought-after material used in manufacturing batteries.

According to Schneberger, rare-earth elements are “not hard to find, but they are very hard to extract cost effectively and turn into a salable product.” Overwhelmingly, the processing of these metals and the manufacturing of magnets is done in China. He said today, the Asian nation produces 92% of all permanent magnets, an overwhelming dominance that could be a huge strategic problem if the nation ever decided to cut off supply. This is why it’s critical to secure reliable and commercially viable domestic sources of these materials.

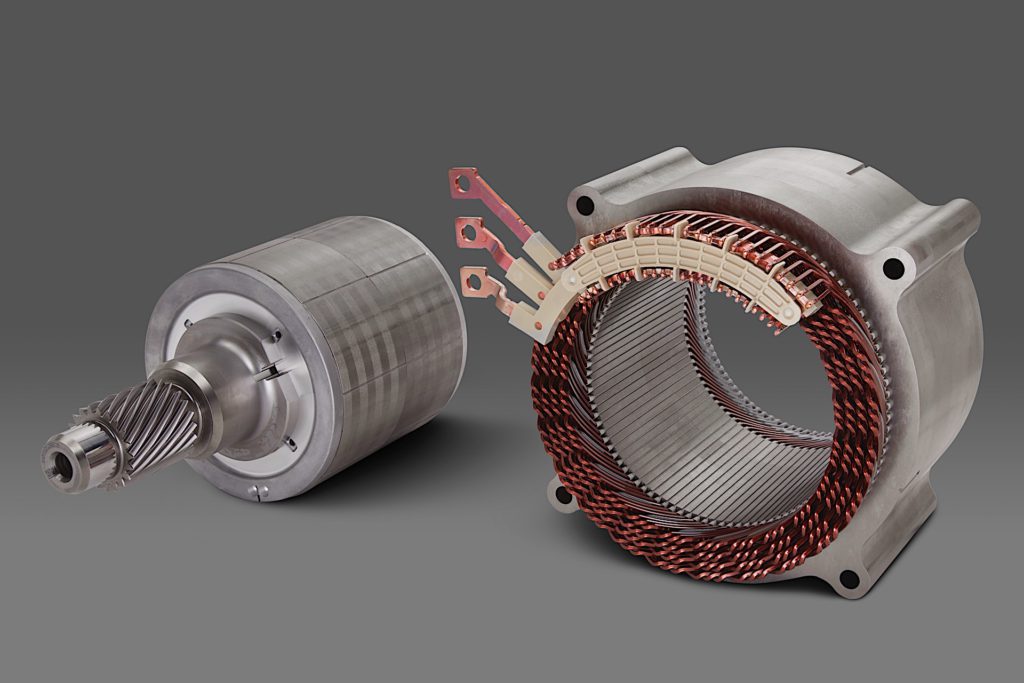

Magnets containing rare-earth metals are ideal for use in electric motors that power modern EVs. Schneberger said so-called permanent-magnet motors are “significantly more efficient” than similar induction motors that use electricity to generate the magnetic field required for operation. If a vehicle’s motor is more efficient, you get better range and can possibly downsize the battery pack, further improving vehicle efficiency.

Of course, there are many, many other uses for rare-earth metals. They’re found in aircraft, speakers, electronics and military hardware like artillery and guidance systems, to name but a few applications, meaning demand is all but guaranteed to grow in the coming years, which will exacerbate the current situation.

To help alleviate significant future shortages, “We are in the process of constructing a rare-earth magnet-production facility in Stillwater, Oklahoma,” explained Schneberger. Once manufacturing is underway next year, the company expects to rapidly scale up, extracting and refining its own rare-earth elements sourced from its Texas mine starting in the second half of 2025.

Schneberger said they plan to produce 600 metric tons of magnets annually, ramping up to a full capacity of 1,200 tons. After that, they’ll duplicate the production line until they’re churning out 4,800 tons of magnets per year. Beyond that, he said they’re already looking at an additional manufacturing location, because even 4,800 metric tons of batteries annually “is only a single-digit percent of the market,” meaning many more rare-earth mines and production facilities will be needed to power the ongoing electric vehicle revolution.

Readily available but difficult-to-process rare-earth metals are critical to making EVs as well as countless other electronic devices. These elements, along with lithium and others, are strategically significant, meaning it’s critical we develop local sources, which is exactly what USA Rare Earth is aiming to do.

Updated (11:50 a.m. Eastern, 6/15/2023): USA Rare Earth clarified that estimated magnet production figures are annual numbers, not daily as initially stated.