On Thursday, Honda outlined some ambitious targets for its upcoming hydrogen fuel cell designs. Working with GM, the vehicle and power-products manufacturer is aiming to double the durability of its next-generation stack while simultaneously reducing the cost to just one-third of the system that powered the 2019 Clarity Fuel Cell vehicle.

To be certain, those are some bold targets, and the company hasn’t explained exactly how it will achieve them, but refining and improving existing designs is probably what will drive these results, opposed to some magic bullet solution.

Beyond this upcoming system, which is being developed in partnership with GM (the two automakers have been working together on fuel cells since 2013), Honda’s subsequent design is even more impressive. Its next-next-generation fuel cell aims to double durability while halving the cost, meaning one of these systems should be four times as tough and just one-sixth as expensive as what powered a 2019 Clarity. That is real progress, folks.

SEE ALSO: Sony Honda Mobility’s new brand is called Afeela and it’s heading to the U.S.

As for sales projections, they are, at first, fairly modest. By the mid-2020s, Honda is looking to deliver around 2,000 fuel cell setups annually. By 2030, sales are estimated to increase to about 60,000 examples per year, and then by the latter half of the 2030s, Honda is looking to sell a few hundred thousand fuel cell power systems annually.

A major hurdle preventing the widespread adoption of fuel cells is a lack of hydrogen. Aside from California, filling stations are appallingly rare. This infrastructure will have to mature before fuel cells ever take off in significant numbers.

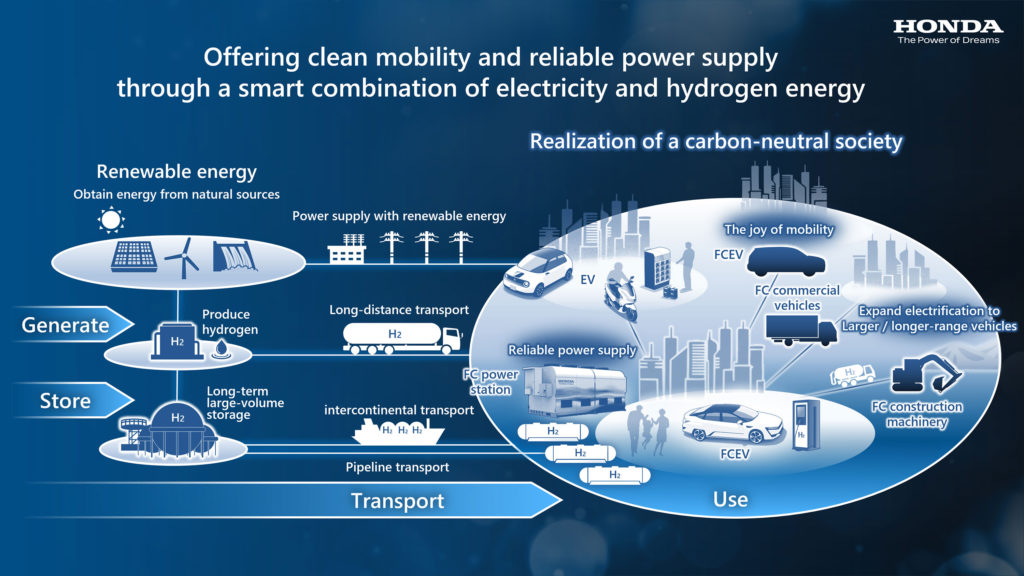

Naturally, Honda’s new fuel cell designs will be used to propel eco-friendly passenger cars, but there are other applications where these pollution-free powerhouses are an ideal fit. Stationary power-generating stations, commercial vehicles like over-the-road trucks and construction machinery are all opportunities. The latter two categories are particularly intriguing because batteries don’t scale as well as hydrogen fuel cells. Equipping, say, a tractor trailer with enough lithium-ion electron reservoirs to haul a full load would not only be prohibitively expensive, the packs themselves would be ungodly heavy, impacting payload. Similarly, backhoes or bulldozers don’t need to haul around more weight, plus it would be very difficult to charge these machines out on a jobsite where there’s no electricity, much less a 480-volt line for DC fast charging. Additionally, hydrogen tanks fill up quickly, basically as fast as replenishing a vehicle with gasoline or diesel, meaning there’s less downtime than with pure-electric vehicles, which no matter how quickly they charge, still take time to absorb energy.

CHECK THIS OUT: 2022 BMW iX xDrive50 review: The future is now

To push the use of fuel cells forward in the commercial space, Honda is working with both Isuzu and Dongfeng to test the technology’s viability in large vehicles. Before the end of the automaker’s next fiscal year (March 31, 2024), Honda is looking to start testing a fuel cell-powered Isuzu heavy truck in Japan. Ahead of that, last month in China, Honda initiated testing of a Dongfeng commercial truck powered by a next-generation fuel cell system.

The technology isn’t viable for a lot of drivers right now, but hydrogen fuel cells offer tantalizing benefits in many applications, especially off road. If hydrogen can be generated in an eco-friendly way and distributed widely, the technology has a great chance of not only taking off but dramatically cleaning up transportation. Fuel cells will also play an important role in helping Honda go carbon neutral across “all products and corporate activities” by 2050.